Pack House Efficiency Software

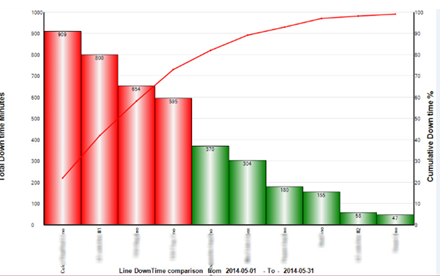

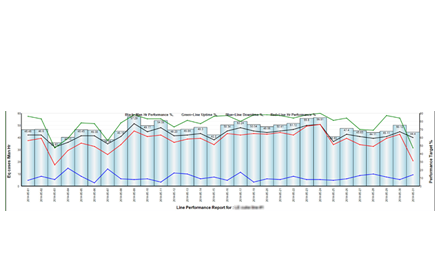

Labour cost is often a big portion of the total sku cost. It is also a highly variable cost. Factors such as line downtime, bottlenecks, and employee performance can cause significant day to day swings in productivity.

i2i Sinope provides pack house supervisors and managers with real-time information on employee performance and line efficiency so they can quickly take corrective action.

i2i Sinope also provides simple and objective performance feedback to line employees in real time via dashboards. This real-time feedback can be a great motivator helping drive pack house efficiency.

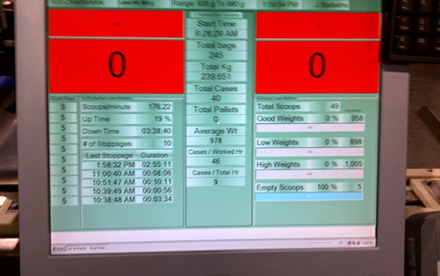

i2i Sinope integrates directly with most pack house weighing equipment such as bench scales and inline check-weighers. Pack weight reports helps minimize product giveaway and product returns due to under weights. This real time weighing accuracy feedback to employees also help to improve the employee’s performance.

Real time packing line status:

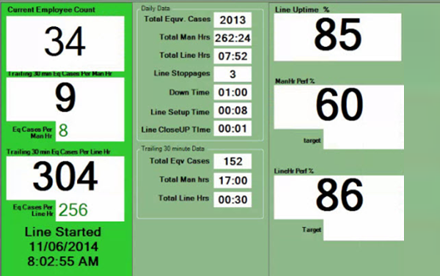

- Real time view of cases packed.

- Real time view of Line output vs capacity.

- Real time view of Employee productivity vs targets.

- Real time view of Line downtime duration and reason.

- Real time data for supervisors to create and revise work schedules

Fast and accurate Sku cost reports:

- Labour cost by Sku.

- Labour cost per Kg.

- Labour cost Actual vs Budget.

Employee Performance monitoring:

- Quickly establish and review targets for each activity and crop from actual and current data

- Monitor employee performance vs targets and vs peers

- Real time and automated performance feedback to employees.

Pack line Data Collection Automation:

- Captures data directly from most packing lines.

- Easy to use employee login screens

- Affordable and non-proprietary hardware.

- Large screen real time dashboards for employee feedback.

Quick features

- Customized for your operation

- Direct data links to most Packing lines

- Affordable hardware

- Real time performance dashboards on each line

- Real time reports on any terminal

- Real time information dashboards for managers

- Attendance and payroll reports

- Automated email reports

- Food safety checklists

- Packing quality checking.

- Onsite training.